Like the saber saw, the variable-speed drill works at a variety of speeds, depending on how hard you squeeze its trigger. Small holes in wood are bored at the fastest speeds; slower speeds are better for drilling large holes in wood and for any hole in metal or masonry.

Tools for outdoor projects: The Variable Speed Drill

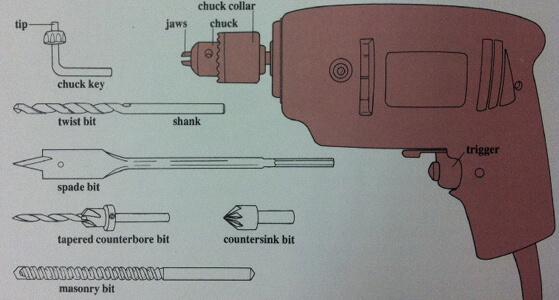

The 3/8 –inch drill at right can accommodate bit shanks from 1/64 inch to 3/8 inch in diameter. Within that range, many different bits are available to drill holes from 1/64 inch to 1 ½ inches in diameter in wood, metal or masonry. Power drills can also hold the shanks of such accessories as buffing wheels, grinding wheels and hole saws.

In this volume, the drill is most often used to drill the hole for a wood screw that fastens together two boards. This task actually requires three holes: one in the bottom board to grip the screw’s threads tightly, and two successively wider holes in the top board for the shank and head. You can use a separate twist bit for each hole, then broaden the top hole with a countersink bit. More simply, you can bore all three holes at once with a counterbore bit, which matches the shape of the screw’s threads and shank, and has an adjustable head that bores, or counterbores, a recess for the screwhead. Avoid cheap counterbore bits; They tend to clog.

Spade bits bore holes up to 1 ½ inches in diameter; because these bits tend to wobble, use of a drill guide is advisable. The model at right, below, will fit any drill with a threaded shaft.

Masonry bits, with closely spaced, carbide-tipped edges, grind slowly through brick and concrete, which would crumble around a twist bit.

Masonry and spade bits are most often sold singly; countersinks are sold in only one size. Counterbore and twist bits are sold singly and in sets that include the most frequently used sizes.

The Variable Speed Drill: A power drill with five bits.

A power drill with five bits.The 3/8 inch variable speed drill holds twist, spade, counterbore, countersink and masonry bits with shanks up to 3/8 inch in diameter. To insert a bit, turn the chuck collar to open the jaws, push the bit shank between the jaws and tighten the collar by hand until the jaws grip the shank. Then push the tip of the chuck key into one of the three holes in the chuck, and twist the key handle. To change bits, loosen the collar with the chuck key before turning it by hand.

The Variable Speed Drill: Using a power drill.

Using a power drill.Clamp the work to a table and indent the wood at the starting point with an awl. To govern a hole’s depth, wrap tape around the bit at the required distance from the tip. Set the bit in the dent, squeeze the trigger and push the drill straight down with steady, moderate pressure. To drill holes for a wood screw (inset). Use a tapered counterbore bit. Or drill two holes of increasing size, a narrow one in the bottom piece for the screw’s threads and a wide one in the top for the shank. Widen the hole’s mouth with a countersink bit if it will be puttied, or use a third twist bit if it will be plugged with a short dowel.

The Variable Speed Drill: Attaching a drill guide.

Attaching a drill guide. Remove the drill’s chuck. (Most unscrew from the shaft of the drill, but check the manufacturer’s instructions.) Twist the guide bracket onto the drill shaft; screw the chuck onto the bracket’s shaft. Slip the guide rods through their holes in the bracket, loosen the thumbscrews on the base, set the ends of the rods flush with the bottom of the base, and tighten the screws; this procedure ensures that the holes drilled are perpendicular to the work surface when the drill guide is upright (inset). If you want to drill to a certain depth, position the stop on the guide rod after you have inserted a bit in the chuck.