The easiest way to get wood cut to size is to have it sawed at a lumberyard. To avoid this extra expense, however, you may decide to cut the pieces yourself, using a circular saw. An inexpensive, compact and portable circular saw, though designed for rough carpentry, will cut the pieces for many projects with reasonable accuracy.

Tools for outdoor projects: The Circular Saw

The standard circular saw for home use has a 7 ¼ -inch blade that will cut through lumber up to 2 inches thick; for bevels, it tilts to any angle from 45? to 90?. To saw without binding, the motor should develop at least 1 ½ horsepower.

A variety of blades is available for different cutting tasks. Carbide tipped blades, although more expensive, will outlast ordinary steel blades and save money in the long run.

In operating the saw, a firm grip is extremely important. A 7 ¼ -inch model weighs about 10 pounds and seems heavier when used at arm’s length. For the added safety of a two-handed grip, buy a saw that has two handles.

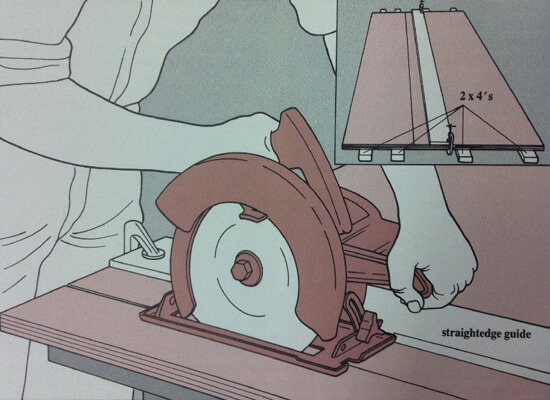

A circular saw can be guided freehand for short cuts; for longer cuts, clamp a guide to the workpiece for accuracy. The manufactured edge of ¼ -inch plywood makes a good, straight guide. Always support lumber from below; without support, the board or panel may crack. Work the saw so that its heavy motor passes over the guide if you are using one.

Many accessories for circular saws are available at hardware stores. A patented metal guide can replace the wood straightedge shown at right. Another guide simplifies rip cutting. A circular saw table, which holds a circular saw underneath it upside down, offers a few advantages of the professional’s tool stability and accuracy at a lower price, but with some loss of versatility.

A circular saw.Driven by a powerful motor, the blade of a circular saw cuts on the upstroke. A spring-activated guard, which slides up into the housing of the saw during operation, drops back down over the blade as the cut is finished. The angle adjustment knob lets the shoe plate be tilted for beveled cuts. The arbor bolt, which holds the blade in place, unscrews so that the blade can be changed.

Blade styles.A fine-toothed plywood blade slices through plywood without splintering it. A crosscut blade’s small teeth tear smoothly across the grain; a ripping blade’s larger teeth, set at a sharper angle, saw with the grain. A combination blade both rips and crosscuts, with small teeth separated by deep indentations. A toothless masonry blade scores brick and stone with its edge of abrasive silicon-carbide grit.

Adjusting blade depth.Loosen the depth adjustment knob. Lay the shoe plate flat on the wood and push up the blade guard. With one hand, hold up the guard while grasping the blade housing to support the saw body. Keeping the shoe plate flat, raise or lower the saw body and with it the blade until the blade is about ¼ inch below the bottom surface of the board to be cut. Retighten the depth-adjustment knob.

Sawing with a straightedge. Clamp a straightedge to the board to be cut so the blade falls on the waste side of the cutting line. Put on goggles before sawing. To cut a large panel of plywood (inset), rest it on the floor, on 2-by-4s. Holding the saw firmly, cut slowly along the straightedge. Do not force the blade it may bind. Keep a steady grip on the saw as it clears the board, and prepare to catch its unsupported weight.